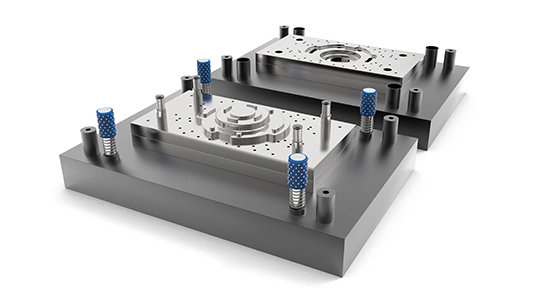

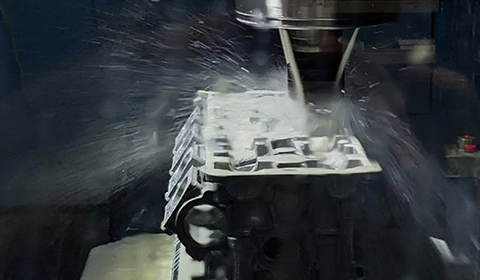

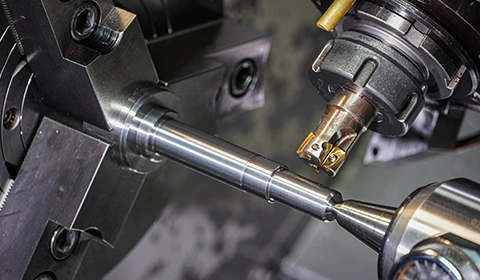

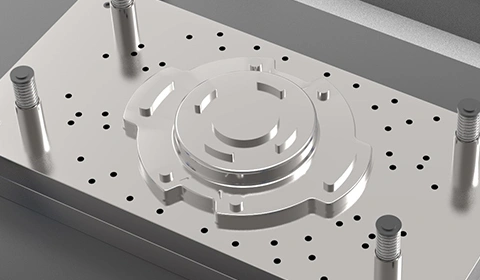

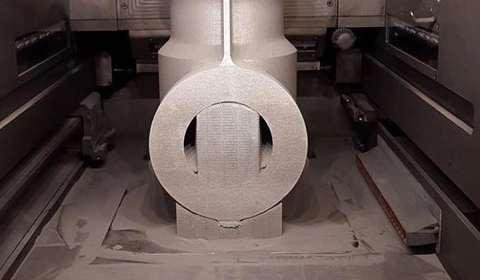

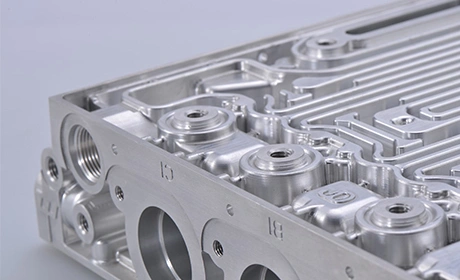

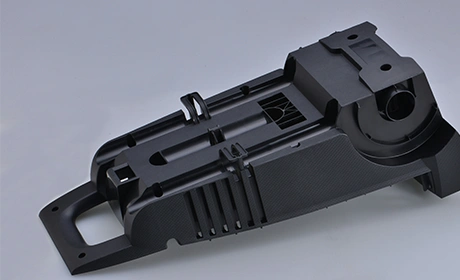

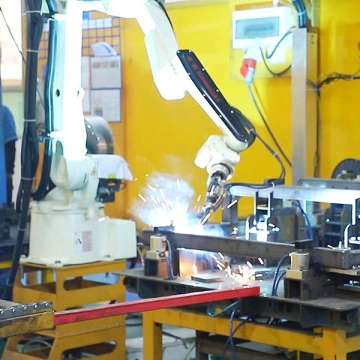

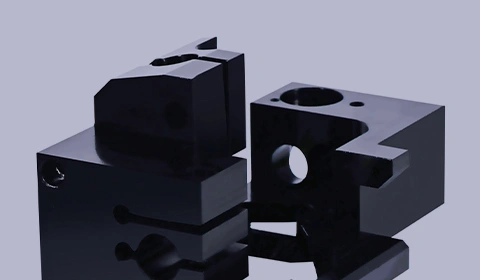

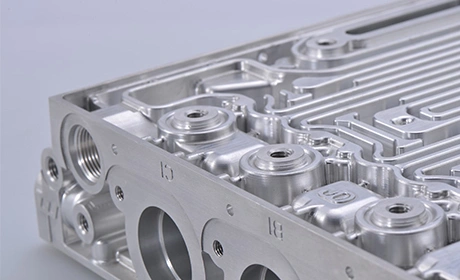

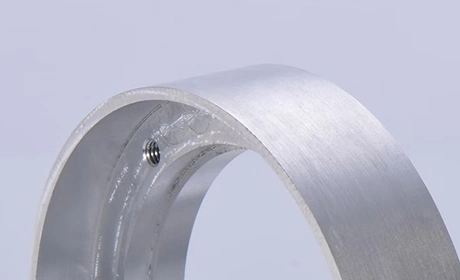

Centre d'usinage composite fraisage-tournage, 3 axes standard, 5 axes continus, fraiseuse 3+2 axes, perçage et post-traitement

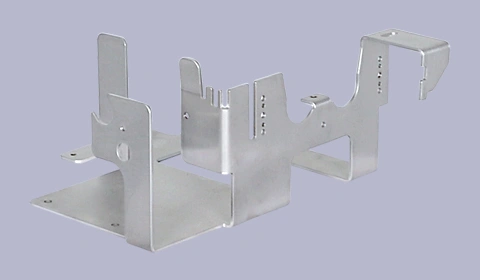

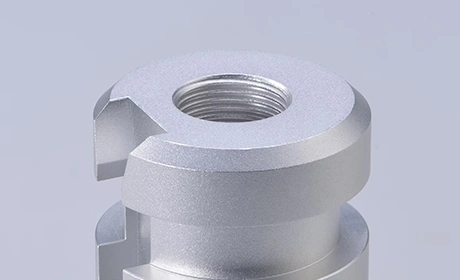

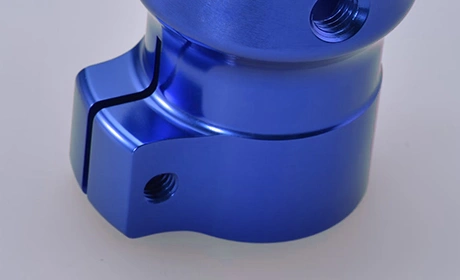

Plus de 50 types de matériaux et plus de 12 traitements de surface ;

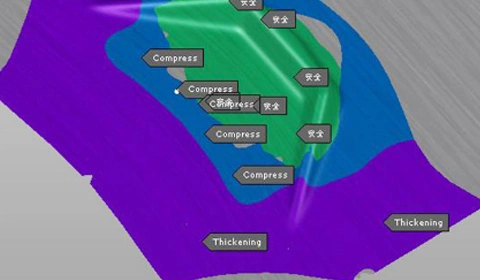

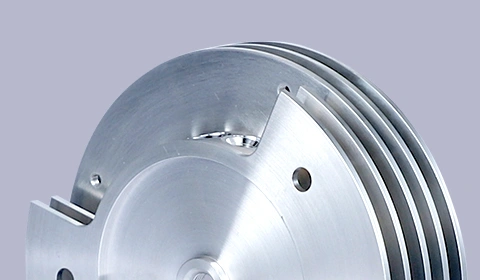

Précision d'usinage : ± 0,0000394 po (0,001 mm), équipé d'un centre d'inspection de haute précision de grade 1,5 um